MOL Drybulk, the bulk shipping division of Japan’s Mitsui O.S.K. Lines is continuing to move forward with its efforts to expand the deployment of its wind propulsion technologies to reduce emissions from bulk carrier operations. In the latest development, MOL Drybulk and UK-based Drax Group have agreed to work together to reduce the emissions and fuel costs associated with shipping biomass by deploying wind power technology on the vessels with a goal of cutting emissions by a fifth.

Known as the Wind Challenger, MOL has been leading efforts in Japan to develop a rigid sail that can be mounted on the deck of its bulkers to assist with wind propulsion to reduce the vessel’s fuel consumption and in turn emissions. MOL is nearing the deployment of the first of its Wind Challenger installations later this year after years of testing and will data from the first vessel to expand the effort.

“MOL Drybulk’s hard sail technology has the potential to transform the maritime industry, cutting emissions and fuel costs and supporting global efforts to address the climate crisis,” said Will Gardiner, CEO of Drax Group. “This partnership to advance this crucial new technology will support Drax’s commitment to reduce its own supply chain emissions and could also deliver far-reaching benefits across a number of different sectors that rely on ships to carry goods to customers around the world.”

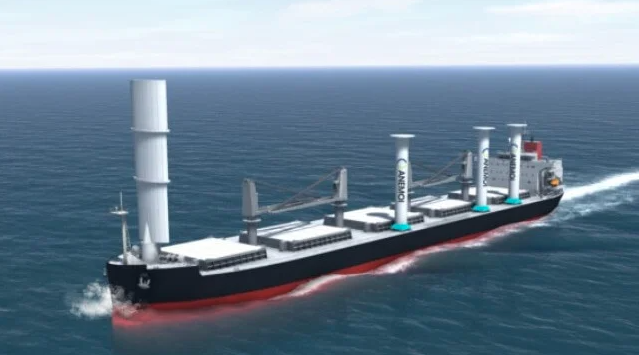

Under the Memorandum of Understanding, the two companies will study the feasibility of deploying a first and second-generation environmentally-friendly bulk carrier to carry Drax’s biomass. The first vessels will use MOL’s automated telescopic hard sail technology, Wind Challenger, and will evaluate the application of other technologies including rotor sails.

First vessels will deploy the Wind Challenger rigid sail while they explore additional technologies and alternative fuels (MOL)

The second-generation vessel aims to at least halve emissions with new vessel designs that use multiple Wind Challenger sails, other low-carbon technologies in development, and the use of alternative fuels such as ammonia, liquefied natural gas, and synthetic fuels.

“MOL has been working with our partners to develop the Wind Challenger technology for over a decade, and it’s great to see this become a reality,” said Kazuhiko Kikuchi, President and Representative Director of MOL Drybulk. “This partnership will help us have a positive impact on how wood pellets and other cargoes are transported across the world.”

MOL Drybulk’s work will include developing the technologies that will be used and liaising with the shipyard where the vessel will be built and fitted with the hard sail technology. Drax will work with the ports and terminals in the supply chain on the operational feasibility studies.

The companies plan to facilitate the development of wind-powered vessels to transport bulk cargoes of Drax’s wood pellets to its customers in Japan, where the biomass is used to generate reliable, renewable energy, which displaces fossil fuels. The goal is to deploy the first vessel with wind-assisted propulsion for Drax by 2025.

The first bulker being built to incorporate the Wind Challenger will operate for Tohoku Electric and is scheduled to enter service before the end of 2022. MOL has reported that it is also working with its long-term customer Enviva, a global renewable energy company specializing in sustainable wood bioenergy, to develop and deploy an environmentally friendly bulk carrier. MOL has said that it is also working together with Indian company Tata Steel to develop an environment-friendly bulk carrier to transport raw materials to the steel mills. Both of these vessel designs also incorporate the Wind Challenger. MOL recently said that working with Enviva it was studying adding wind rotors to a bulker also fitted with the wind challenger.

Source: The Maritime Executive