Machinery onboard ships require to increase their efficiency and maintain the cost of operation, which includes unnecessary breakdowns and spares can be reduced. For different types of machinery and systems, various measuring tools, instruments, and gauges are used on a ship.

Below, we have compiled a list of mechanical measuring instruments and mechanical gauges which are extensively used on the ship.

Ruler and scales: They are used to measure lengths and geometrical parameters. They can be a single steel plate or a flexible tape-type tool. They are usually available in the measuring scale of inch or cm. They are used for quick measurement of parts and are always kept with other measuring gauges or tools in the workshop for handy access. The ruler and scales are not used where precise measurements are required. It is made from stainless steel which is durable and will not rust or corrode.

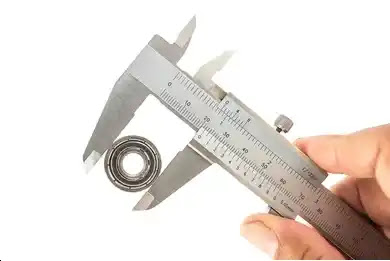

Calipers: They are usually of two types- inside and outside calipers. They are used to measure the internal and external size (e.g., diameter) of an object. It requires an external scale to compare the measured value. This tool is used on those surfaces where a straight ruler scale cannot be used. After measuring the part (body), the opening of the caliper mouth is kept against the ruler to measure the length or diameter. Some calipers are integrated with a measuring scale; hence there is no need for other measuring instruments to check the measured length. Other types are odd leg and divider caliper.

Vernier Caliper: It is counted in the list of quality measuring instruments, which are used to measure small parameters with high accuracy. It has got two different jaws to measure the outside and inside dimensions of an object. It can be a scale, dial, or digital type Vernier Caliper.

Micrometer: It is an excellent precision tool that is used to measure small parameters and is much more accurate than the vernier caliper. The micrometer size can vary from small to large. The large micrometer caliper is used to measure large outside diameter or distance.

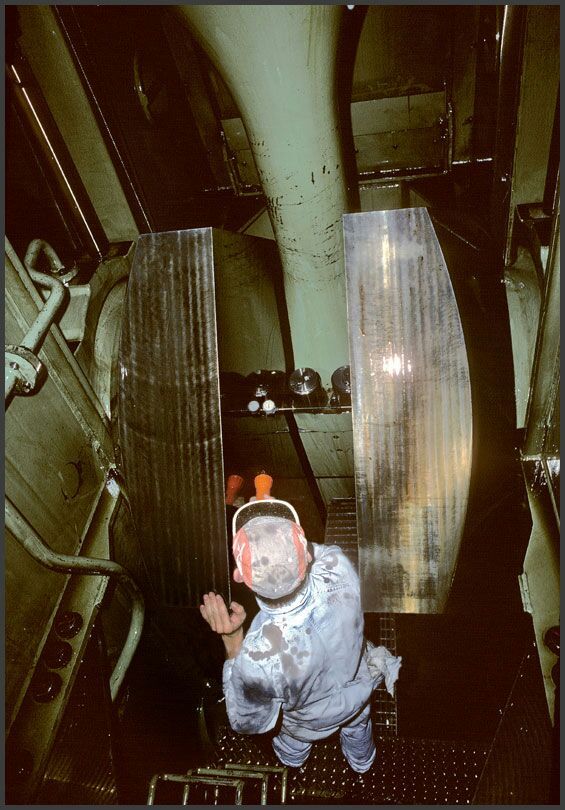

Poker Gauge: Poker gauge is one unique tool among different types of measuring instruments available in mechanical or digital form on ships. It is used to measure propeller stern shaft clearance, also known as propeller wear down. It is a type of depth measuring instrument, whose reading indicates the wear down of the stern shaft. The design of the poker gauge may vary as each vessel has a customized poker gauge made available during the handing over from the shipyard. While taking the reading the shaft is to be turned so that the propeller boss matches the marking of the shaft.

Bridge Gauge: As the name suggests, a Bridge gauge looks like a bridge carrying the measuring instrument at the center of the bridge. They are used to measure the amount of wear on the main engine bearing. A feeler gauge or depth gauge can be used to complete the process.

Liner Measurement Tool: A liner measurement tool is a special tool for marine engines which comes in a set of straight rods of different marked lengths, which can be assembled together to make the measuring tool of the required length. It is used to measure the wear down or increase the diameter of the engine liner.

American Wire Gauge: AWG is a standard tool that is circular and has various slots of different diameters in its circumference. It is used to measure the cross-section of an electric cable or wire. This tool is usually kept in the electrical workshop of the ship, and the electrical officer uses it for measuring wire thickness.

Bore Gauge: A tool to accurately measure the diameter of any hole is known as a bore gauge, it can be a scale, dial, or digital-type instrument. The most common type which is used on the ship is dial type bore gauge, which comes with a dial gauge that is attached to the shaft and replacement rods, also known as measuring sleds, of different sizes to measure different hole dimensions.

Depth Gauge: A depth gauge is used to measure the depth of a slot, hole, or any other surface of an object. It can be of a scale, dial, or digital type. The depth gauge can be a micrometer style type, a dial indicator type, or a modified vernier type tool, which means the measuring base is fitted on the reading scale of a micrometer, dial indicator, or vernier scale.

Angle Plate or Tool: As the name suggests, this is a tool comprising of two flat plates which are at a right angle to each other, and it is used to measure the exact right angle of an object or two objects joined together. This tool is usually kept in the workshop away from any tools or chemicals which may roughen the surface of the angle plate.

Crankshaft Deflection Gauge: A form of dial gauge specifically made to measure the crankshaft deflection of the marine engine. The working is similar as explained in the dial gauge, the only difference is the construction which let this tool hang between two webs allowing it to measure the deflection when the crankshaft rotates.

These are some of the types of primary tools and gauges that are used on board ships. If you feel we have missed any vital tool, then let us know, and we will add it to the list.